[ad_1]

Disc brakes have gradually taken over from rim brakes in the pro peloton since the UCI first allowed them to be trialled in 2015 and they’ve become the default option offered on most mid-level and top-tier road bikes, but is there continuing technological innovation to support their use? We’ve looked at patents from Shimano, SRAM and Campagnolo to find out.

Manufacturers claim that disc brakes offer better braking than rim brakes, particularly in wet conditions or on long alpine descents. Of course, they’ve been used on mountain bikes and some non-race road bikes for years but their widespread adoption on performance road bikes is much more recent. The UCI confirmed that disc brakes were authorised for road racing on a permanent basis only in 2018.

All of the top-level pro teams now use disc brakes, Ineos Grenadiers having finally made the switch, and many road bikes released over the past two or three years have done away with a rim brake model altogether. The 2023 Giant Propel launched in mid-August, for example, is available only with disc brakes.

The road bike industry has clearly made up its mind about where it wishes to head and the market has shifted in the same direction – when the same bike is available in disc brake and rim brake formats, it’s always the disc brake version that sells better – but are the key brands working on further disc brake tech?

Patent publications for disc brakes

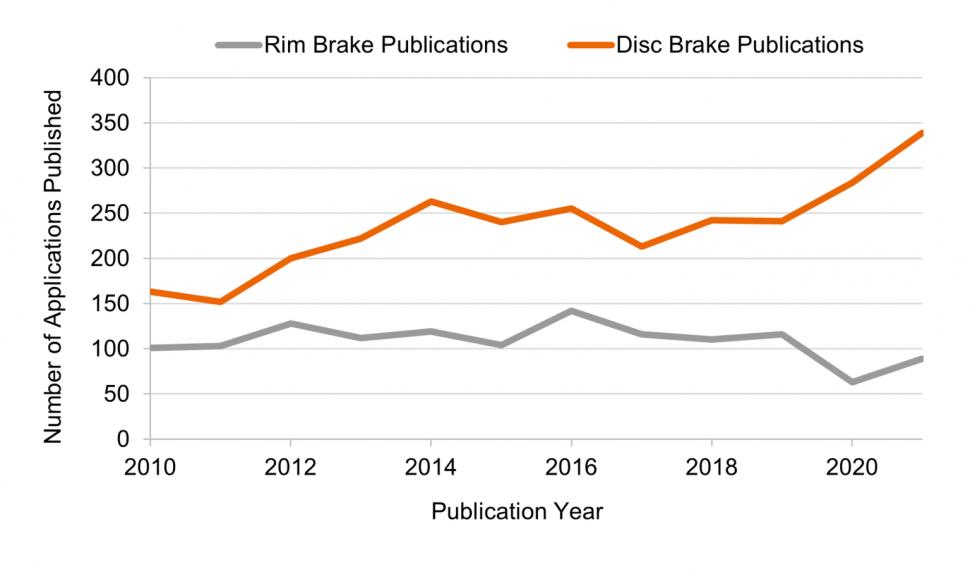

Below is a graph showing the number of patent applications published since 2010 in the class of ‘brakes specifically adapted for cycles’ for both rim brakes and disc brakes. The recent widening of the gap between the numbers of disc and rim brake publications mirrors the current ethos of bicycle manufacturers.

The increase in disc brake-related publications around 2014 can be explained by a rise in innovation levels around the release years of first-iteration disc groupsets for the road. These release years are indicated in the graph below.

Check out our review of Shimano’s Dura-Ace R9200 Groupset

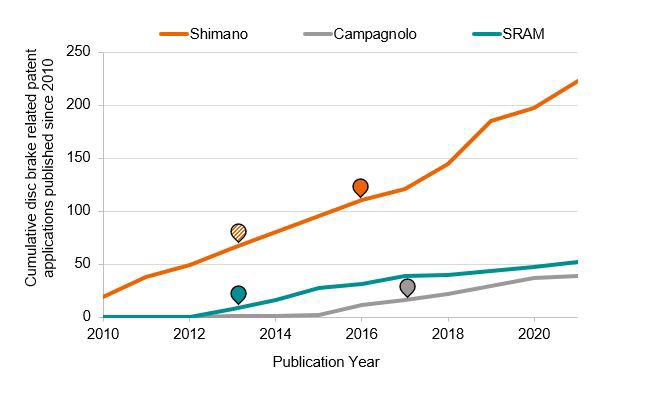

Shimano, SRAM and Campagnolo are the three best-known groupsets for the western market. The graph below shows cumulative disc brake patent publications for these three manufacturers since 2010.

Also indicated with solid markers are the release years of disc brake options for each manufacturer’s top-tier groupsets. The striped marker for Shimano corresponds to the 2013 release of BR-R785 (below), its first hydraulic disc brake for road bikes as opposed to its full top-tier groupset offering released in 2016.

Since, and even before, this early release, Shimano has shown relatively consistent innovation in the field. However, it is worth noting that some of their publications, particularly before 2016, can be attributed to its mountain bike disc brake groupsets.

Find out how the SRAM Rival eTap AXS groupset performs

SRAM, on the other hand, has been much steadier in its rate of publication of disc brake applications, though had minimal relevant publications before its early market entry in 2013.

While Campagnolo was the last of the three key groupset brands to introduce a top-tier disc brake groupset, the rate of its relevant patent publications has since picked up. Appearing unfazed by its later market entry, Campagnolo’s director of global marketing said the company’s objective was not to be the first but to offer the best product.

It is unsurprising that Shimano overall vastly outpaces SRAM and Campagnolo in terms of disc brake-related patent publications; with its dominant market share leading to around $4 billion (around £3.4 billion) in sales in 2021, it can afford to innovate at a far greater scale.

What does the innovation address?

Critics often argue that the claimed improved braking performance of disc brakes in road cycling is outweighed by safety concerns, overheating problems, and the simplicity of maintenance of the rim brake. We can explore a few of the published patents to assess whether or not these issues are being addressed by component manufacturers.

In current implementations, disc brake bikes weigh more than their rim brake counterparts. Frames and forks also require increased frame thicknesses to cope with the torsional loads while braking – which begin to add up in a sport famous for its focus on ‘marginal gains’. Manufacturers must surely be looking to shave any gram possible from disc brakes.

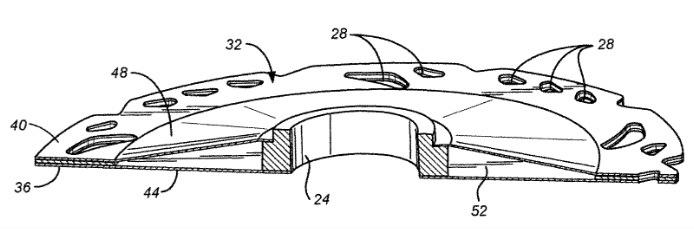

US Patent US 9777784 B2, courtesy of Shimano, seeks to address this weight issue with a disc brake rotor with hollow portions.

The figure above shows a cross-section of a disc brake rotor with a hollow chamber 52 formed between a central portion 24 and the braking surface 32. The effect is decreased weight while maintaining adequate stiffness of the rotor.

However, US 9777784 B2 also discloses a more subtle effect arising from this embodiment. Disc brake rotors can heat to high temperatures during heavy braking, and thermal stresses can warp the rotor out-of-plane.

This warping can result in the brakes squealing and rubbing on the calliper pads. The patent suggests that the hollow portions 52 may combat this overheating. Within the hollow chamber cooler, denser air near the central portion 24 will circulate radially towards the braking surface 32 by centrifugal force.

The braking surface, where all the heat is generated, can therefore be cooled more efficiently without the added weight of alternative cooling structures.

When should you get new disc brake rotors?

The patent goes further, to add that the hollow chamber 52 may be filled with a liquid coolant material for even better thermal management. This application was originally filed back in 2011, and while we are yet to see such a novel system implemented in products from Shimano, it is interesting to see that they had the foresight to tackle problems arising in disc brakes before their widespread use extended from mountain biking to the road.

Find out everything you need to know about disc brakes with our definitive guide

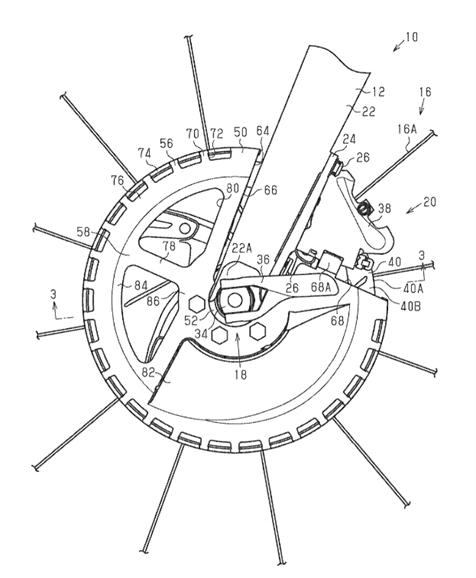

Another problem also often cited by proponents of the traditional rim brake is safety and the worry that a rapidly rotating metal rotor could harm a rider caught up in a crash. Shimano has tried to address this problem in US Patent US 10746241 B2, published in August 2020.

As displayed above, a rotor 40 is enclosed within a rotor cover 50, to limit contact of a rider’s fingers, for example, with the rotor 40. This solution appears simplistic at first, but upon further inspection, it includes more sophisticated features. In particular, the rotor cover includes a multitude of openings 72, 80.

Too many openings and the cover could generate too much turbulent drag as the bicycle cuts through the air, whereas none at all would affect rotor cooling from rapidly passing air. A fine balancing act must therefore be met between aerodynamic efficiency and cooling of the rotor.

Does the bike industry really want to force you on to disc brakes?

A feature of note is the sweeping shroud 82 at the bottom of the cover, designed to direct air towards the rotor, presumably for enhanced cooling.

The solution presented by US 10746241 B2, therefore, addresses safety concerns without apparent compromise in thermal regulation of the rotor. Again, however, such a system is yet to see used in either the professional peloton or on everyday commutes.

When routed externally, hydraulic hoses connecting the handlebar controls to the disc brake callipers can cause aerodynamic drag and most people prefer the aesthetic of internal routing. Whilst this is not an issue exclusive to disc brake systems, the market is now demanding a clean look with the hoses hidden away inside the frame and fork. Campagnolo has also been busy filing applications for disc brake patents, one in particular to address this issue.

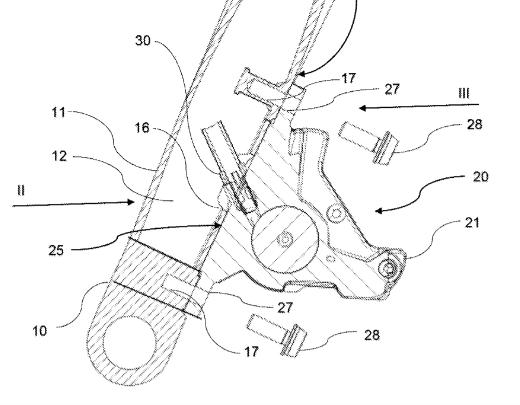

US 10442493 B2, as shown above, discloses a calliper 20 mounted on a portion of the bike fork 11, and a connector 30 for a hydraulic hose. The connector 30 is however located completely within the fork 11, such that the hydraulic hose may be fully internally routed. There’s no hose at all on show.

Internal routing can make some maintenance tasks more time-consuming but Campagnolo appears to have doubled down on aesthetics with this patent application – an indication that it believes discs are here to stay.

The next step – implementing the innovations

The shift from rim to disc brakes has clearly been a priority for manufacturers. The uptick in patent applications indicates a willingness to innovate by big brands to stay ahead of the competition, but it will be interesting to see to what degree this innovation trickles down into off-the-shelf products. The bicycle industry is actively trying to address the problems that are cited.

For example, in its latest top-tier groupset release, Shimano made subtle improvements to its hydraulic brakes, such as providing an all-new one-piece calliper that “maximises stiffness and reduces weight” and that provides a marginally wider pad clearance that “decreases the chance of rotor rub”.

However, all of these patents showing that the big players are continuing to refine their disc brake systems suggest that they agree, at least to some degree, with four-time Tour de France winner Chris Froome’s statement that “the technology is not quite where it needs to be”.

What issues would you like to see the big brands address with their next-generation disc brakes? And do you think there’s a future for rim brakes on mid to high-level road bikes? Let us know in the comments below.

[ad_2]

Source link