[ad_1]

To many, linkage forks are a thing of the past. Brands like Trust have had a go at creating and selling a modern linkage fork but ceased manufacturing shortly. But could there be a solid application for a linkage suspension fork for gravel bikes? RockShox and SRAM seem to think so.

We’ve found some patent drawings submitted on November the 10th outlining a new linkage fork from SRAM that’s designed specifically for gravel bikes.

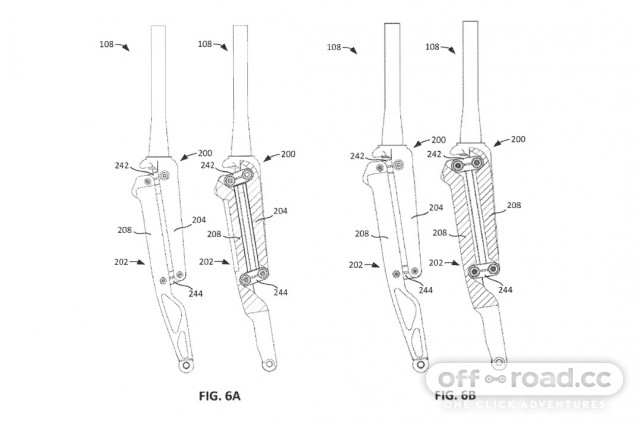

First off, let’s take a look at how the linkage works. It looks to use a three or four-piece design with the main crown assembly and two legs that are attached using four linkages. From this drawing, it looks fairly simple.

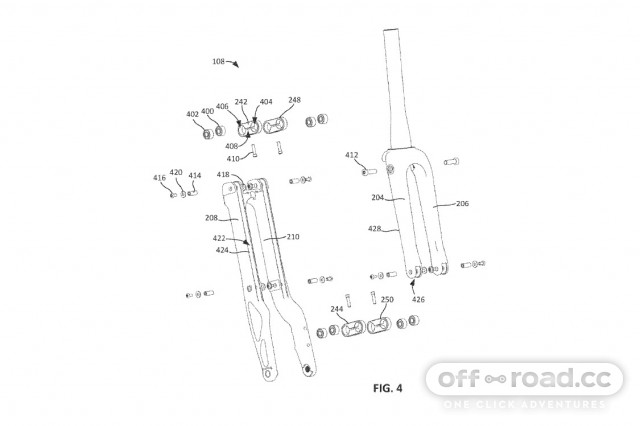

From this exploded drawing we can safely assume that the linkages rotate around cartridge bearings.

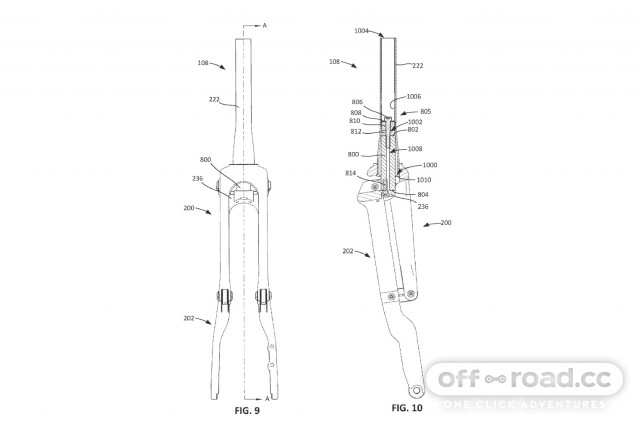

Here, we can see that there’s a spring built into the steerer tube of the fork, where all of the damping comes from. The patent suggests that this damper uses shear springs, potentially with a parallelogram shape. It’s said that this spring can be built of a compliant material, using urethane or a thermoplastic as an example. In some examples thought up by SRAM, the spring rate is dictated by flexible links, an idea that isn’t a stone’s throw from what Lauf uses on its True Grit and Carbonara forks.

SRAM’s patent application outlines the downsides of telescopic forks, firstly saying how they’re expensive to manufacture but also that they’re designed to suit a wide range of travel, often from 100mm up to 200. As such, they’re not suitable for bikes that don’t require as much squish.

Telescopic forks also require a certain amount of breakaway force before they can get the wheel tracking the ground. It’s said that bikes that are designed for road riding – or we might think, gravel – may struggle to exert enough force to get the suspension moving properly, thus transmitting small bumps through the bike rather than plush suspension. As telescopic forks legs and stanchions are round in shape, they’re also not ideal aerodynamically.

The idea behind creating a linkage in this respect is to reduce that breakaway force as it’s drastically reduced in bearings. The suspension would be freer to absorb bumps and chatter, and this design can allow for a more aerodynamic shape.

Another benefit of the linkage that’s not stated in the patent (or it’s very well hidden) is that it may not be much taller than a standard non-suspension fork, so it could be used with a wider range of bikes, without altering their static geometries because the fork doesn’t necessarily need to be taller to accommodate its travel. I could be wrong here, though.

As always, we’ll keep you updated on any fresh findings.

You might also like:

[ad_2]

Source link